De-risking the Labor Shortage–It’s All about Flow

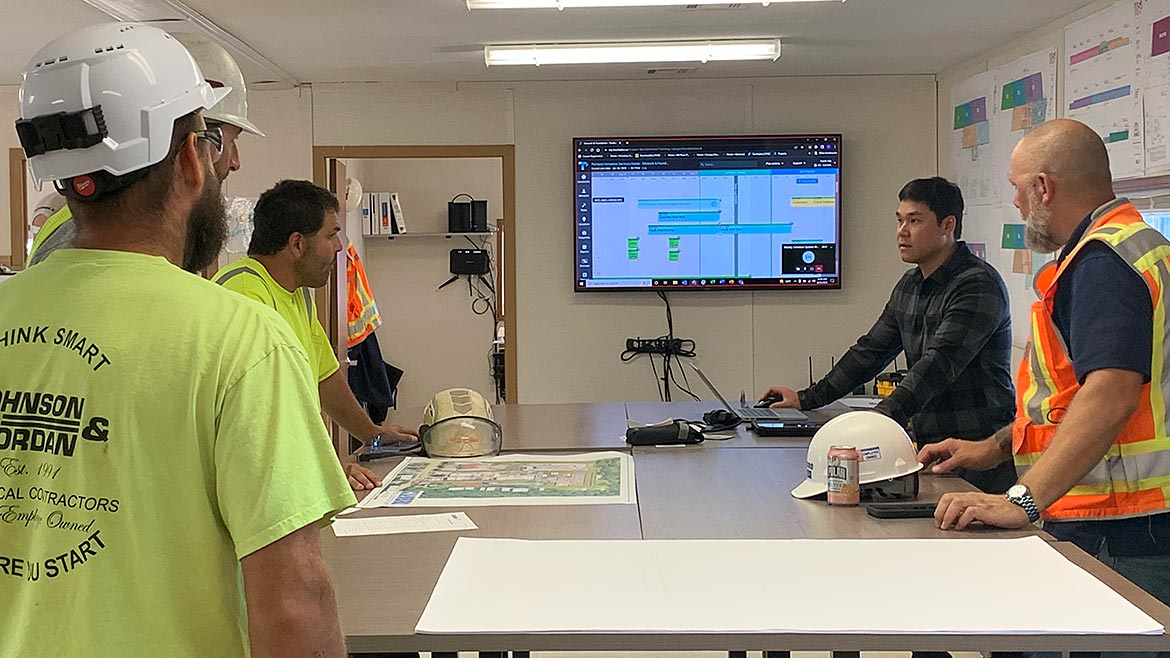

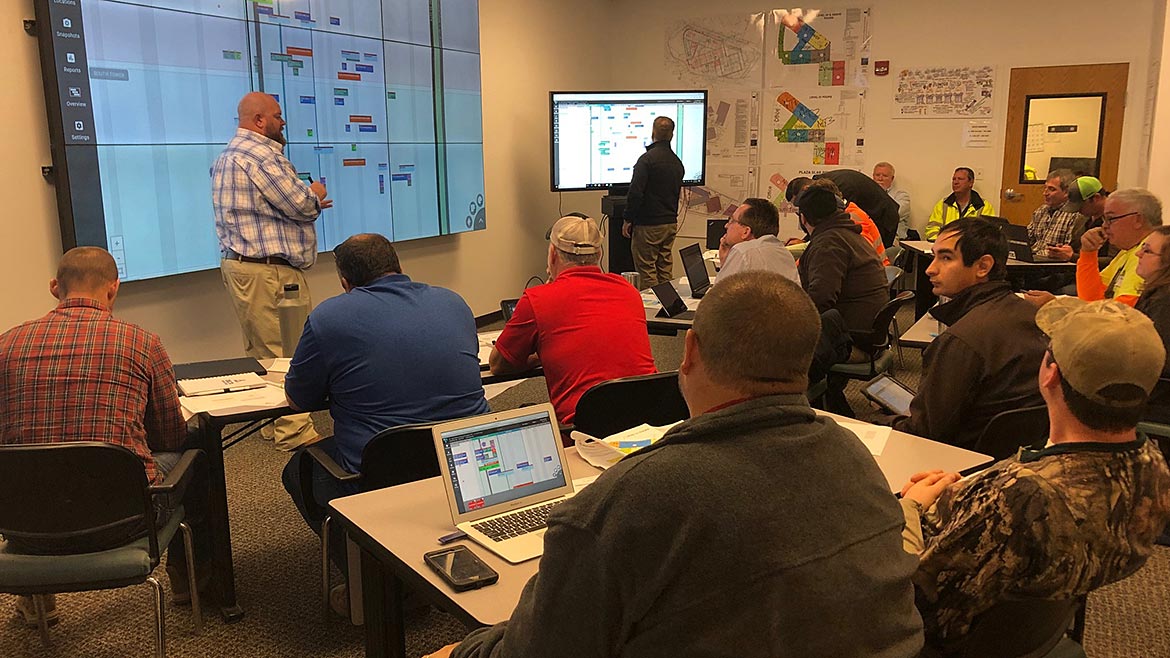

Labor optimization can be coordinated with technology.

Persistent labor shortages, combined with ongoing supply chain uncertainty, can greatly increase the risks of construction project delays, accidents and litigation. In years past, materials and equipment were more readily available, as were the sufficient trade skills needed for their installation. Now, those supply chain inputs have long lead times and volatile delivery schedules, and it has never been harder to flow the right skills to the right place at the right time to install them efficiently and safely.

The labor flow problem is a data problem. When the information in the contract schedule and production plan are disharmonious, the quality and timeliness of critical decisions suffer, in both the office and the field. In addition, this is inevitable with the manual, ad hoc production planning methods traditionally used in the field. Superintendents and trade supervisors often struggle with the efficient task assignment, sequencing and execution that is needed to match the unpredictable arrival of materials and equipment, and master planners and schedulers lack the timely, accurate visibility of labor availability and utilization needed to maintain the contract schedule.

.jpg)

Across the industry, the consequences of this data problem are many, including:

- Trade Stacking – Worker productivity declines and safety risks increase when multiple trade crews must be assigned to work in the same area at the same time to stay on schedule. This happens when supply chain data is uncoordinated with labor availability data and when master schedulers and production planners lack a shared, timely, collaborative view of all project data.

- Rework – Data in the contract schedule about the work to be done on the project can be quite general and is often ambiguous, and production planners must frequently implement their best guess regarding labor scheduling and assignment. As a result, it is common for certain work to be done out of sequence with other integral tasks. That work must then be redone, resulting in needlessly increased project costs and delays.

- Productivity Loss Litigation – With costly trade skills in such short supply, specialty contractors must use their available workforce more carefully than ever. However, when a general contractor uses manual production planning, errors in trade crew scheduling can easily occur. Sometimes, this results in a large trade crew idle on the job site for hours or hastily relocated to other, often far away projects. This can bring significant, additional costs to the specialty contractor that they must try to claw back through litigation against the general contractor.

Solving These Problems

The solution to these and many other problems is what we call Digital Labor Flow Optimization. DLFO replaces ad hoc, manual production planning with easy-to-use software that can be shared by owners, master schedulers and planners, project executives, superintendents, supervisors and workers. Moreover, digital production plan data can be continuously synchronized with contract schedule data. These are the three key strategies for enabling DLFO:

- Digital Lean: The “Lean” construction principles embodied in the Last Planner System, a popular procedural approach to production planning, can demonstrably improve labor productivity. However, traditional Lean planning is a manual process that relies heavily on daily or weekly meetings of project principals. Important new information about workforce issues and changes cannot be shared and acted upon in real-time as they happen, leading to many delayed or erroneous decisions. Fortunately, contractors now have access to a growing variety of cloud-based, mobile planning software, like Touchplan and others, that enable everyone on the job site to see, follow and change the production plan in real-time as needed from anywhere, eliminating the data latency inherent in manual Lean planning.

- Contech Stack: Many leading contractors are finding great improvements in labor utilization and productivity through the centralized integration of construction technologies for supply chain, scheduling, planning, workforce management and standardizing on common digital information access tools for all workers across all their projects. This reduces the learning curve in the office and the field, and it enables workers to be easily moved between task locations and projects as needed.

- Humans in the Loop: Most master scheduling software systems, like Primavera P6 and others, are based on the venerable Critical Path Method, while the emerging Lean construction software products are based on the Last Planner System. CPM is top-down, command-and-control, long-term planning, while LPS is bottom-up, collaborative, iterative, short-term planning. They both have their place but provide very different representations of labor planning and utilization for any given project. And, attempted automated integration of the two has proven very dissatisfying to the users of both systems due to the resulting increased data complexity and frequent schedule distortion. The key to effectively using the two systems together is through the application of essential human intelligence and expertise to review and guide the data passing between the systems and resolve any conflicts and disparities in the data.

.jpg)

Using DLFO

In our work with leading owners and general and specialty contractors, especially those focused on large, complex projects, like data centers, advanced manufacturing, health care, life sciences and capital infrastructure, we have observed dramatic improvements in schedule, spend, scope and safety through their use of Digital Labor Flow Optimization. Even in the face of persistent supply chain and labor challenges, they have been able to get more work done with fewer workers and greater safety through the improved workforce deployment, event response and problem resolution that DLFO enables.

To firms still struggling with those challenges who are new to the Last Planner System, we recommend they begin their resolution journey in the following way:

- Collaborate: Form an interdisciplinary team comprising finance and risk managers, CPM schedulers and production planners to identify the most significant chokepoints in on-the-ground labor flow for a critical project.

- Investigate: Examine the related data in the master schedule and production plan to discover planning misalignment and measure its impact on labor flow.

- Educate: Engage an expert LPS facilitator, like Construction Accelerator, to teach the team how LPS can improve labor optimization and show them how to synchronize CPM and LPS planning.

Many people may find DLFO new and unfamiliar, but as many leading owners and construction firms have already discovered, its adoption is not difficult, and its undeniable benefits can come quickly with focused implementation.

Images Credit: MOCA Systems

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!