GA Corner

Choosing the Right Fastener for Fire-Resistive Gypsum Systems

Photo courtesy of Gypsum Association

Question: In a fire-resistive gypsum panel system, how do I determine the correct fastener to use and how to use it to ensure I am compliant?

Answer: In fire-resistive gypsum panel assemblies, the fasteners used are just as important as the panels and framing. Using the wrong type or installing them incorrectly can compromise the system’s tested fire performance, potentially leading to code violations, liability issues, or safety risks.

To ensure compliance and maintain system integrity, professionals should refer to two essential documents from the Gypsum Association (GA):

• GA-600 – Fire Resistance and Sound Control Design Manual

• GA-216 – Application and Finishing of Gypsum Panel Products

Step 1: Use GA-600 to Identify the Tested Assembly

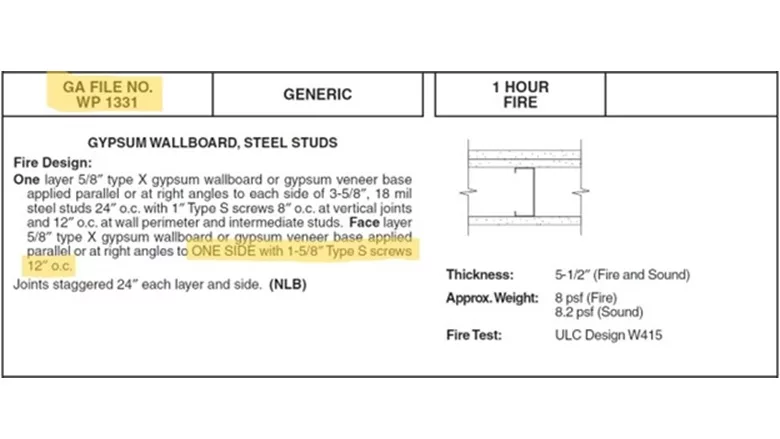

GA-600 lists hundreds of fire-resistive wall, roof/ceiling, and floor/ceiling assemblies that have been tested and listed in cooperation with code officials, manufacturers, and testing agencies. Each system includes specific requirements for framing, panel type — and, for the purposes of this article — fasteners.

In the example below, for GA File No. WP 1331 (ULC Design W415), the fasteners to use are 1-5/8” Type S screws spaced every 12 inches on center. Always refer to the GA File No. (highlighted) to confirm the fastener type associated with the respective proprietary or generic system.

Note: GA-600 includes explanatory notes clarifying that:

• The indicated fastener lengths and sizes are minimums.

• Screws meeting ASTM C1002 Standard Specification for Steel Self-Piercing Tapping Screws for Application of Gypsum Panel Products or Metal Plaster Bases to Wood or Steel Studs shall be permitted to be substituted for the prescribed nails, one-for-one, and , when the length and head diameter of the screws equal or exceed those of the nails specified in the tested system, and the screw spacing does not exceed the spacing specified for the nails in the tested system.

Any deviation below the prescribed fastener minimums can void the assembly's tested fire rating.

Step 2: Use GA-216 to Confirm Installation and Application Standards

While GA-600 tells you what fastener to use, GA-216 tells you how to use it.

Section 2.1.6 of GA-216 defines a fastener as “a nail, screw, or staple used for mechanical application of gypsum panel products” in accordance with ASTM standards. The specific ASTM standards for each can be found in the following sections of GA-216:

• 2.2.8 – Nails

• 2.2.9.1 – Type G, S, and W screws

• 2.2.9.2 – Type S-12 screws

• 2.2.10 – Staples

After identifying the correct fastener from GA-600, use GA-216 to confirm proper installation. Key sections include:

• 4.8.4.1 – Nails shall be driven so that nail heads are slightly below the surface of the gypsum panel product without breaking the facer or fracturing the core.

• 4.8.4.2 – Screws shall be driven so that screw heads are slightly below the surface of the gypsum panel product without breaking the facer, fracturing the core, or stripping the framing member around the screw shank.

• 4.8.4.3 – Staples shall be driven such that crowns are parallel to framing members and bear tightly against the gypsum panel product without cutting into the facer or fracturing the core.

• 4.8.5 – Fastener type and spacing for fire resistance rated assemblies shall be in accordance to the specified fire rated design.

Why It Matters

Fasteners that are overdriven, undersized, or spaced incorrectly not only risk inspection failures but can compromise the fire resistance of the entire system. Following GA-600 and GA-216 ensures compliance, life safety, and liability protection.

For more information, watch the Gypsum Association’s instructional video on fasteners by clicking here, and explore additional videos on the GA YouTube channel for other highlights from GA-600 and GA-216.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!